- Home

- Knowledge library

- Cooling targets for grain storage

Cooling targets for grain storage

It is important to cool grain as quickly as possible in stores. Discover how temperature affects insects, mites and fungi, and how to use grain cooling targets to minimise grain quality losses.

How storage temperatures influence common grain hazards

Above 40°C: Most insects die within a day

33–25°C: Most insects breed rapidly

25–15°C: Mycotoxin formation is most likely

15–12°C: Most insect species stop breeding, although grain weevils may still reproduce (although slowly)

5°C: In moist grain, mites and fungi may still increase (although slowly)

Below 5°C: Insects stop feeding and mites stop increasing

Temperature monitoring

- Monitor every few days until target reached, then weekly

- Always record at the same location

- Take measurements where cooling takes longest – furthest from the fan in blowing systems, usually 0.5 m beneath the surface and centrally between ducts

- Use a calibrated grain temperature probe (thermocouples or thermistors)

Increased temperatures may indicate presence of fungi, sprouting or development of grain weevils.

Grain cooling targets (short-to-long term)

Ideally, cooling should commence as soon as the grain comes into store. This permits grain to be stored at higher moisture contents and effectively increases the safe storage time. It also evens out or equalises temperature gradients and reduces moisture translocation. Use low-volume aeration (10 m3/hour/tonne or 6 ft3/min/tonne) to cool grain as soon as ducts are covered.

- Within 2 weeks of harvest – cool grain to below 15°C to reduce insect activity (e.g. prevent saw-toothed grain beetles completing their life cycle)

- Within 3–4 months of harvest – cool to below 12°C to stop insect activity (e.g. prevent grain weevils completing their life cycle)

- By the end of December – cool to below 5°C* to help kill adult insects and prevent mites increasing

*Malting barley cooling/moisture targets and germination

A natural condition, dormancy prevents grain sprouting in the ear. Malting barley is purchased based on a germinative capacity test (ideally, viability is 100%). Germination should be tested before storage, after three months’ storage and/or prior to delivery. Usually, stored barley grain is not cooled to below 10°C, as it can increase the risk of inducing secondary dormancy. Ideally, for long-term storage, malting barley is dried to about 13% MC. Germination capacity declines rapidly at higher moisture contents and temperature.

Influence of grain bed depth

If the depth of grain is too great, cooling success may be reduced. At greater depths, distance between ducts needs to be reduced (see table, below)

|

Grain depth (m) |

2.0 |

3.0 |

4.0 |

5.0 |

6.0 |

7.0 |

8.0 |

|

Duct spacing from centres (m) |

7.6 |

6.3 |

5.5 |

5.0 |

4.4 |

4.0 |

3.7 |

Data typical of commercial systems that use a 250 mm diameter by 920 mm high perforated metal duct served by a fan working at 70 mm WG designed to cool about 95 tonnes of grain in 100 hours of ventilation. Follow supplier’s recommendations for specific products.

Oilseed rape has a much higher resistance to airflow than cereals. If using an aeration system designed for conventional cereal storage, reduce the bed depth by 50–70%.

How differential controls improve cooling and make savings

A differential controller/thermostat switches on the cooling fan when the ambient air temperature is lower than the grain temperature. Compared with manual control, this reduces the number of fan hours required to reach the target temperature and energy costs.

- Place the ambient sensor close to the fan inlet, but not in a position where it is affected by heat generated from the fan

- Place the probe in the region of the grain bulk that is the slowest to cool, but not too close to the surface (to avoid tracking of the ambient temperature)

The use of differential thermostats on cooling fans at a differential setting of 4–6°C provides the most rapid, cost-effective and carbon-efficient cooling. If blowing with cooler air, using a differential thermostat (4–6°C difference), it is far less likely to dampen grain. For grain to become damp from blowing, you need a combination of:

- Excessive aeration rates

- Condensation around ducts (especially in spring)

- Rain driven into uncovered external fans

- Successive days of condensing fog

Sucking air through grain may increase natural dampening at the grain surface during winter – this front may extend to one-third of grain depth.

Pros and cons of vertical aeration systems

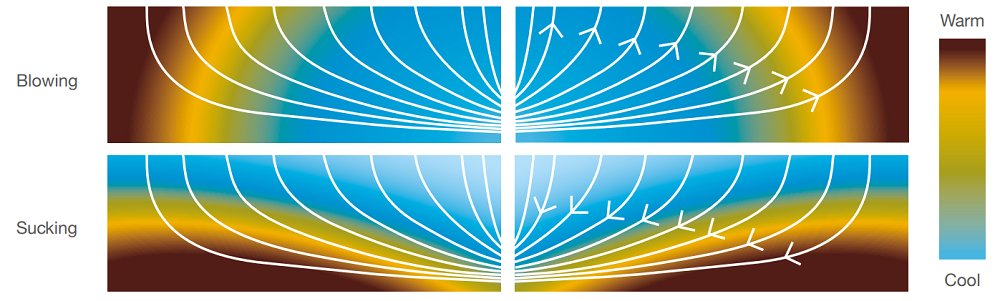

Vertical aeration systems can be just as effective as horizontal systems. The advantages of vertical systems are that the capital costs are lower and the risk of damaging ducts during unloading in flat stores is reduced. Spacing of ducts will depend on grain depth. However, placing ducts 4–8 m apart is often suitable for an average flat store of grain. Blowing and sucking systems are available, which affect the progress of cooling through the grain.

Blowing air

- Improves air distribution – cools 20% more grain than sucking

- ‘Problems’ rise to the surface

- Fan heating reduces relative humidity of blown air

- Warm, damp air is flushed from the building

- Cooling can start as soon as ducts are covered

Sucking air

- May increase dampening at the grain surface during winter and this dampening front may extend to one-third of the grain depth

- Is useful if condensation on the inside of roofs is a problem (although good ventilation can overcome this) or there is a risk of water entering aeration ducts

- Use if grain depth is so great that excessive temperature rise would occur with blowing

Airflow

- Fans need sufficient pressure to overcome resistance, due to the crop, the depth and the duct characteristics

- Ducts need to be of sufficient diameter and have sufficient perforated area to minimise resistance

- Measure using an anemometer in a measuring duct, of appropriate diameter and length, placed in front of or after the fan

- A floatmeter should not be used to measure airflow for low-volume aeration

Above: Progress of grain cooling with blowing and sucking systems after 100 hours of ventilation in a bed 3 m deep (arrows indicate airflow paths).

Topics:

Sectors:

Tags: