- Home

- Knowledge library

- Highly heritable barley quality traits

Highly heritable barley quality traits

Some quality characteristics, such as nitrogen concentration, specific weight and screenings, are highly heritable in barley. Learn about the genetic (varietal) and other factors that affect these traits, as well as the typical market specifications.

Growth guides for wheat, barley and oilseed rape

Grain nitrogen concentration

Benchmark: Grain N offtake = 132 kg/ha

Varietal influence: High

Other influences: Nitrogen (N) supply and timing, rainfall

N concentration can be manipulated for specific end-user quality specifications.

During grain filling, N is redistributed from stems, leaves and chaff to the grain. Root systems remain active during grain filling, so high soil N availability late in the season can lead to high grain N.

Feed barley crops can take up to 35 kg N/ha from the soil after flowering. Malting crops take up less because N is applied earlier and at lower rates.

High grain N concentration can arise from a large uptake or redistribution of N late in the season or poor starch deposition. However, it can also result from drought, lodging or disease, all of which reduce yield without affecting N redistribution. Lodging risk may increase in crops grown for high N specification.

Apply all N fertiliser to winter-malting crops at or before GS31 to reduce the risk of excess grain N concentration.

Spring barley

Grain N concentrations of malting varieties, grown in low N fertiliser regimes, tend to be lower in the North than in the South. The reason may be that greater yield dilution of grain N occurs in the North. In the North, most spring malting barley is sold for malt distilling, with the majority of grain N concentrations below 1.65%.

Most spring malting barley grown in England is destined for brewing, with the majority of grain N concentration requirements between 1.55–1.85%.

Apply all N fertiliser to spring crops at or before leaf 3, unless high grain N is required.

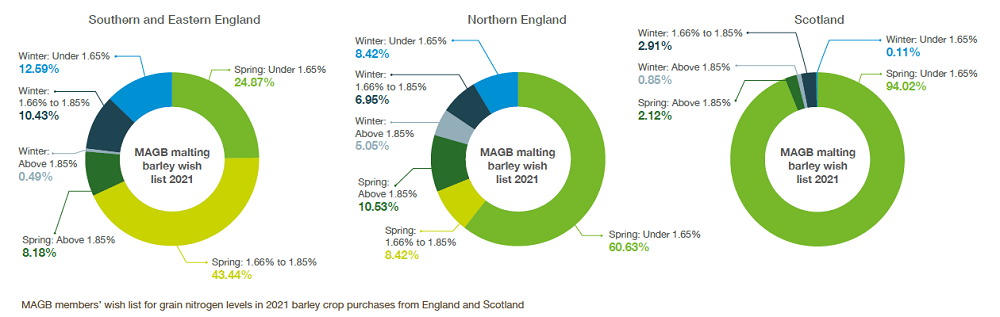

Indication of barley nitrogen levels required by maltsers (2021)

There are three main malting markets, which are differentiated primarily by the variety used and the grain N (N%) content.

- 1.65% and below is used for malt distilling.

- 1.60% to 1.85% is used for brewing.

- Above 1.85% is used for grain distilling.

Visit the MAGB website for the latest information

Nutrient management (RB209) home page

Grain specific weight and screenings

Varietal influence: High

Other influences: Plant population

Specific weight is a measure of individual grain density and how the grains are packed. It is influenced by grain fill, grain size and surface characteristics. Large, well-filled grains have a high malt extract potential. Therefore, screenings need to be minimised.

Small-grained varieties are often associated with high screenings (grains that fall through a 2.5 or 2.25 mm sieve). Grains from the upper and lower parts of ears, as well as from late-formed tillers, tend to be smaller than those from the central part of the ear.

Six-row varieties, which have a high number of grains/ear and grains/m2, tend to produce smaller grains with lower specific weights and more screenings than two-row varieties. The relatively longer grain-filling period in northern Britain reduces these differences. Two-row winter barley and spring barley varieties produce similar specific weights and screenings.

Most feed grain buyers require a minimum specific weight.

Grain skinning

Grain skinning is a defect that occurs when the outer cost (the husk) becomes partially, or completely, detached from the grain at harvest. Skinning decreases malting efficiency by causing variability in germination, the key step in the malting process. As a result, maltsters set maximum levels for skinning.

It is influenced by weather (e.g. intermittent wetting and drying), combine settings (e.g. drum speed) and variety.

- Sow spring varieties that are vulnerable to high screenings as early as possible

- Avoid high seed rates or late sowing of spring barley to minimise screenings

Steve Hoad, SRUC.jpg)

Other quality criteria

Most buyers prefer large grain as this is associated with high levels of carbohydrate and reduces the risk of screenings.

Maltsters prefer varieties with a high malt extract. This increases productivity in brewing and is related to high spirit yield in distilling. Extract is a measure of the amount of sugar obtained from the malt after the mashing process.

Malt extract is influenced by variety choice, grain size and homogeneity, grain N content and enzymes. Large and even-sized grain tends to mill better and produce more extract. Lower grain N increases starch content and extract. The malt should also have sufficient enzymes to adequately convert starch to sugars.

How to measure specific weight and grain N content

Specific weight can be measured by hand using a chondrometer. Grain is, however, routinely measured at intake labs, using an NIR grain analyser, which can give readings for specific weight, moisture and N concentration. Grain can also be sent to a specialist lab for N percentage determination by methods such as Dumas or Kjeldahl.

|

Benchmark data for grain quality characteristics (feed barley) |

Overall |

North |

South |

|

Yield (t/ha) |

8.8 |

9.0 |

8.5 |

|

Average grain weight (mg @ 85% DM) |

46 |

48 |

45 |

|

Grain N (%) |

1.76 |

1.73 |

1.80 |

|

Specific weight (kg/hl) |

65.0 |

65.0 |

65.0 |

AHDB

AHDB

Topics:

Sectors:

Tags: