- Home

- Knowledge library

- Factors affecting feed conversion ratio (FCR) in pigs

Factors affecting feed conversion ratio (FCR) in pigs

The cost of feed is a major contributor to the cost of production. Effective reduction in the feed conversion ratio (FCR) offers financial savings and significantly reduces the carbon footprint of pork production.

Calculating the feed conversion ratio (FCR)

The FCR calculation is relatively straightforward in that it needs two pieces of information:

- The total amount of feed (kg) fed within a given period

- The total amount of pork finished (kg) within a given period

These figures are divided (amount of feed ÷ amount of finished pork) to produce a figure (always greater than 1) of how many kilograms (kg) of feed it takes to produce 1 kg of pork.

Learn how to calculate FCR and use it as a measure of yield

Discover the UK’s national benchmark data on FCR and other key KPIs

Why should pig producers reduce their FCR?

Feed makes up 60–70% of the cost of production, and over 60% of the carbon footprint of pork production comes from feed ingredients. As such, the reduction of FCR makes financial sense and supports sustainable production. As consumers and policy continue to highlight the need for sustainable production, the use of FCR as a proxy for environmental sustainability will become increasingly useful.

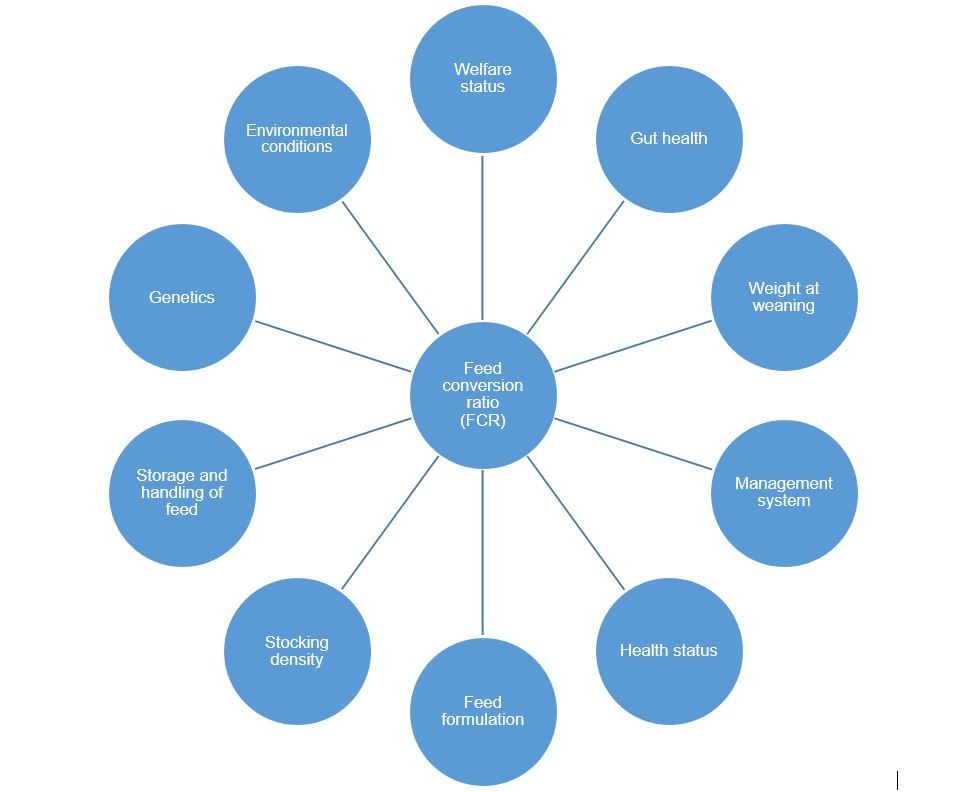

The reduction of FCR, i.e. lowering the amount of feed it takes to produce 1 kg of pork, is challenging. This is because there is no one method for reducing FCR. The diagram below shows the factors that can impact the FCR of finishing pigs:

The list above is not exhaustive and only covers the main areas. To tackle FCR, there are several elements that need to be brought together:

Data

The use of recorded data such as mortality, FCR and performance have to be analysed in such a way that they show the outliers of production. This means using KPIs to identify the good areas (to leave them alone or learn from them) and the underperforming areas (to learn from and target limited labour, to improve them).

A management strategy

Targeted use of labour is key. Management processes such as Lean offer a template to support engaging teams to tackle inefficiencies. These can be strategies to reduce waste and free up labour or targeted interventions designed to improve performance.

Prioritisation of the basics

A good biosecurity system needs be in place to maintain health, well-formulated diets, targeted weaning weights and clear transition strategies at weaning.

Eight top tips for lowering FCR

Tip 1: Make sure as much feed as possible reaches the pig

Feed waste from feed lines, poorly maintained troughs and bins, as well as pests, can all impact the amount of feed that reaches the pig.

Explore strategies to reduce feed waste

Tip 2: Target a higher average weaning weight

Those piglets that wean at 8 kg on average finish up to 10 days earlier than those that are weaned at 7 kg

Tip 3: Focus on good gut health

Plan management strategies that deliver piglets at weaning with well-developed guts. Use transition strategies that support continued gut development, avoiding a post-weaning dip.

Explore the ways to improve gut health without zinc oxide

Tip 4: Ensure a high health status

Ensure a high health status through better biosecurity and clearly defined health management plans formulated with your vet.

Discover biosecurity for pig farms

Tip 5: Explore diet formulation

Explore diet formulation with your nutritionist. Sometimes, replacing a single diet stage with two different formulations can lower input costs and have a positive effect on the FCR.

Learn more about pig diets – specifically at weaning

Tip 6: Maintain a good environment

Appropriate temperature and ventilation have a substantial impact on FCR. A stable temperature and good air movement to minimise ammonia and carbon dioxide at pig height are proven to increase FCR.

Learn more about our ventilation types and guidance

Discover the optimum environment for housed pigs

Tip 7: Plan production flows

Plan production flows carefully and look at the value of lower stocking density. Lower stocking densities have been shown to lower FCR and decrease days to slaughter. Pigs finish faster with lower inputs.

Tip 8: Support staff training

Support staff training not just in technical skills but also in management training. A culture of continuous improvement has been shown to deliver significant returns on investment.

Learn about our range of training courses for stockmen

Impacts of lowering the FCR

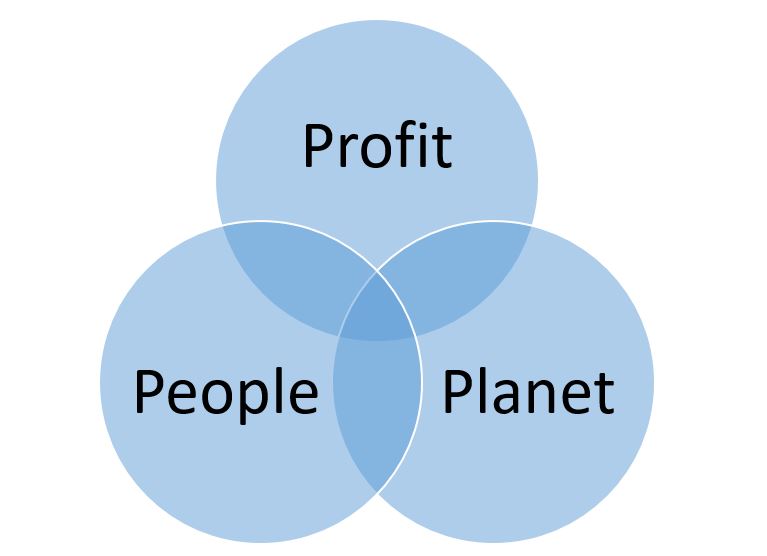

Feed as an ingredient has a physical cost. Lowering the amount of feed needed to make a kilogram of pork (the FCR) gives a financial return. While this is an important motivator, the reduction of FCR should be considered more holistically.

Profit

With 60–70% of costs from feed and the continued volatility of feed prices, reducing FCR allows producers to continue to reduce costs (increasing potential profitability) and reduce the risk of volatile prices.

People

There are two aspects to this element. The first is the staff involved in pig production. The reduction in FCR often takes a broader skill set, especially in process management. An investment in lowering FCR often requires an investment in staff.

The second element is the consumer. In a changing environment, there is an increase in the focus on the sustainability of livestock production. A continued reduction in FCR and a lowering of the carbon footprint helps demonstrate that sustainability to consumers. A commitment to sustainable production helps to guarantee our ‘right to supply’ or social license.

Planet

FCR is a good proxy for carbon footprint. The move to public money for public goods shows the UK government’s commitment to more sustainable production and offers new opportunities for livestock producers.

Further information

The carbon footprint of feed is impacted by its ingredients. Wheat, soya and primary crops impact the climate through land-use change and transport. The use of coproducts such as whey, brewers grains and potato cream all help reduce the carbon footprint of feed.

Research from Queens University Belfast showed that the primary contributor to the carbon footprint of feed is soya meal. Whilst soya meal is a by-product of oil production, it still carries a substantial carbon footprint. It is also a perfectly balanced source of amino acids making its replacement challenging. There has been some limited work in this area, however, and the links to that can be found below:

Green Pig Project – Locally grown forage as an alternative to soya meal