- Home

- Knowledge library

- Post-slaughter factors affecting red meat quality

Post-slaughter factors affecting red meat quality

There are several technologies which can be applied aiming to improve meat quality following slaughter. Depending on the set up of the processing chain, these may be used by themselves or in combination.

Back to: Meat quality and shelf life

Muscle to meat conversion

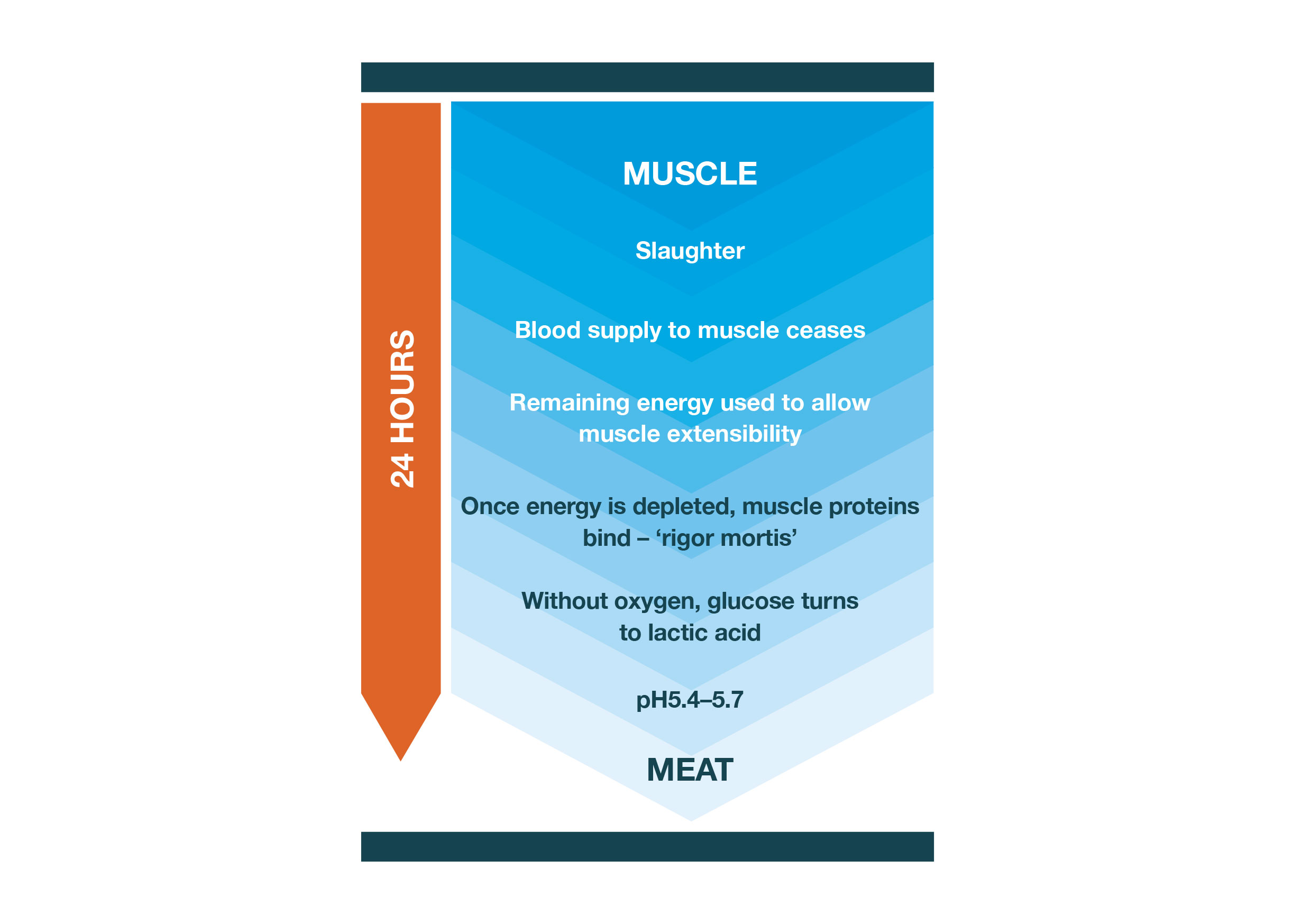

Following slaughter, the supply of blood to the muscles ceases, and any remaining energy is used up. This is commonly seen as muscles twitching/tensing. Once this energy is depleted, muscle proteins begin to bind during a process referred to as rigor mortis.

The pH of living tissue is around 7. When the animal dies, the energy within the muscle is used up and causes the pH to fall to around 5.4– 5.7 (the ultimate pH).

If an animal is stressed prior to slaughter, they use up energy through an adrenaline response. This means that once slaughtered, there is not as much energy available and the pH does not fall as much, typically remaining higher than 5.7. This also has an impact on the meat quality, causing a term referred to as DFD (dark, firm, dry) or DCB (dark cutting beef).

Learn more about stress and meat quality.

Electrical stimulation

Some processors use electrical stimulation after slaughter to improve eating quality. Muscles are stimulated to contract and use up energy which accelerates the onset of rigor mortis and allows earlier chilling.

A high voltage applied during chilling increases tenderness more effectively than a low voltage applied during dressing. In beef, this method is less effective on tenderness than hip suspension.

It is important to monitor the pH fall of red meat carcases to optimise the relationship between stimulation-induced pH change and chilling.

Hip suspension

Suspending a beef carcase from the hip, rather than Achilles heel, stretches muscles and avoids contractions before rigor mortis, leading to increased tenderness in the leg and loin muscles.

Chilling rate

The rate at which a carcase is chilled can impact the state of the muscle contractions and the toughness of the meat.

Meat toughness increases if muscles contract before rigor mortis sets in. Cooling too fast, or too soon, results in muscle ‘shortening’.

As a general rule, while chilling the carcase, avoid a muscle temperature below 10ºC for 10 hours after slaughter. If electrical stimulation has been used, faster chilling is preferable.

Hanging time/maturation

Meat tenderness increases in extended storage as naturally-occurring enzymes break down protein in the meat. Maturation can occur in hung carcases, unpackaged primals or vacuum-packed meat.

Maturing on the bone

- Traditional

- More weight loss due to evaporation

- More waste due to trimming exposed muscle

- Improved tenderness

- Change in flavour

Wet ageing

- In vacuum packs for 7–21 days

- Less evaporative loss

- Less waste due to less trimming

- Improved tenderness

- Change in flavour

Beef

For beef, mature joints for grilling and roasting for up to 21 days. This will give benefits over 7–14 days maturation. Extending this to 28 days will have little additional benefit to tenderness but may impact flavour.

Lamb

Lamb joints benefit from ageing for up to 10 days. This should be limited to seven days for cuts to be sold bone-in. Extending to 15 days will have some additional improvement, but there is little benefit in extending maturation beyond that.

Pork

As well as enhancing flavour, matured pork can have improved water holding capacity. This can be beneficial for processing, as well as the perception of juiciness. Pork loins (bone-in) can be matured for a minimum of seven days and loins without bone, for 14 days. Pork should be matured at temperatures lower than 3ºC to prevent the production of toxins from bacteria.

Avoid maturing parts intended for mince as this may not be cost-effective and always be sure to observe maximum legal limits.