- Home

- Knowledge library

- Pork Key Performance Indicators (KPIs)

Pork Key Performance Indicators (KPIs)

Key performance indicators (KPIs) provide a clear and direct measure to determine whether you are meeting your business goals.

What are KPIs?

KPIs measure your performance against key business objectives; they are a measurable value that indicates whether a business is achieving its key goals.

KPIs allow a business to focus its attention on what parameters matter most for success, and provide an analytical basis for decision making and improvement.

A robust KPI provides a direct indication of business efficiency, sustainability, and profitability, the elements critical for success.

Why use KPIs?

Using KPIs allows for effective decision-making. Their use reduces the complexities of business performance to a small, manageable number of key indicators.

As an example, for a plane flight, the pilot uses a wide range of data to assess where the plane is on the planned route. For this, indicators like GPS, speed, fuel levels and weather conditions allow the captain to identify the plane's exact location. From this, the pilot knows what decisions are needed to reach the end destination successfully. This is the same for business, and KPIs (like the pilot's data) indicate whether the business is on a successful voyage or veering off course.

For KPIs to work, the measures chosen must align with the overall mission of the business. A pilot would not use levels of refreshments available on-board as an indicator for reaching the destination. So for a business, it is essential to identify what KPIs are crucial to success.

What are the pork industry’s KPIs?

For the pork industry, there are four KPIs fundamental to business performance and improvement.

Performance (Financial):

Pence per kilogram (ppkg) or £/head

Survivability:

Medicine use (mg/kg) or % mortality

Productivity:

Piglets per sow per year or weaned per pen

Yield:

Daily Live Weight Gain (DLWG) or Meat Per Tonne Fed (MPTF)

Financial performance is the most important of the four KPIs.

This is because there is no point maximising the other KPIs if the cost of achieving this is more than the value of the end product.

Simplistically no business should spend £1 to make 40p, as this is unsustainable.

Each key KPI has different measurements

Performance - Financial

Financial KPIs show if your business is profitable, and are the most important as they are linked to all other KPIs, as they all have costs associated with them. Financial KPIs can be a measure of how much it costs to produce each kg of pork or cost per weaned pig.

Visit the Performance (financial) KPIs page

Survivability - Health and welfare

Health and welfare KPIs can be a measure of how much medicine is required to produce each kg of pork or the percentage of mortality. Medicine usage is a good indicator of the effectiveness of health and welfare across a unit, and a high use tends to indicate issues with diseases and welfare.

Visit the Survivability KPIs page

Productivity - Fertility/herd performance

Fertility includes measures such as pigs per sow per year or pigs weaned per pen. The measures provide a straightforward measure of the business viability, as, without fertility, there would be no viable business. However, it is possible to maximise fertility at the cost of profitability, so fertility should always be compared to your financial KPIs.

Visit the Productivity KPIs webpage

Yield - FCR and DLWG

The key to measuring yield KPIs is weighing stock. There are key points that lend themselves to gathering weight data more than others. Measures can be the number of grams per day a pig grows known as Daily Live Weight Gain (DLWG) or a measure of the efficiency of feed converted into meat (FCR).

Can KPIs improve business efficiency?

To improve business efficiency, we first need to understand the overall process to produce the end product. All products are made through a process, take making a bacon sandwich as an example; it is produced by the following process:

Bread is cut and buttered -> Bacon is fried -> Bacon is stacked -> Sauce is added

The final stage of the process is the service of the product: a bacon sandwich.

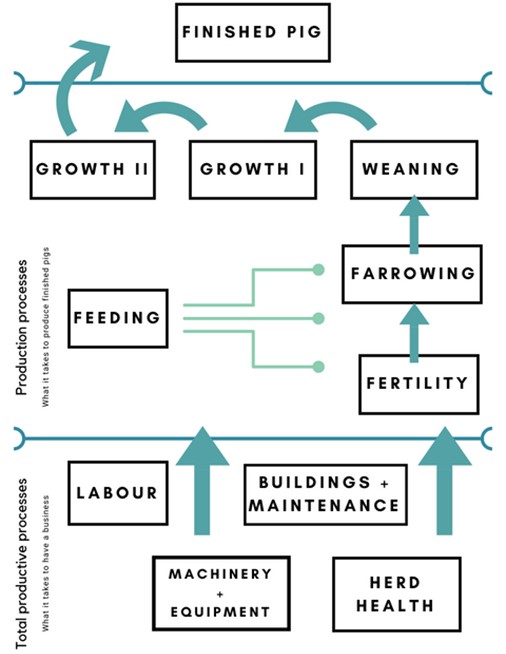

The same applies to pork production; it is an extensive process made up of the following three elements:

1) Total productive processes

The things that make up your business; buildings, labour, machinery, and the maintenance process that allows your herd to exist, i.e. herd management

2) Production processes

The things that make a finished pig; these processes may have many steps but are the broader processes that make finished pigs, e.g. feeding, weaning, fertility etc

3) The product

This may be the finished pig, for a farrow to finish system, or could be piglets for a breeding unit.

Simplified process map for farrow to finish pig production:

To improve business efficiency, we need to look at the process which needs to improve.

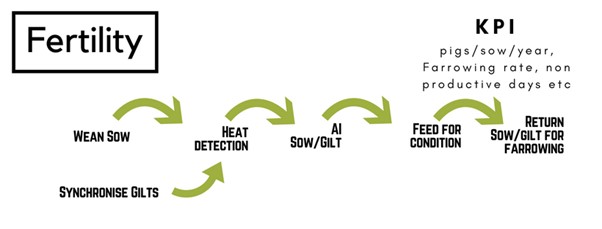

If we use productivity (fertility) as an example, we need to undertake the following steps:

- Check which other processes will be impacted i.e. increased fertility will increase the pressure on pig places in the growth stages. Can the weaning and growth processes manage the increase in requirement?

- Break the process down into steps, i.e. what does it take to have a fertilised/served sow?

Which KPI monitors the efficiency of each process?

Most processes will be clear, e.g. fertility will be monitored by productivity KPIs such as piglets/sow/year, whereas other processes, such as labour, may seem more complicated. All processes will have a financial performance KPI such as pence per kilogram (ppkg) and labour, buildings and machinery are no different.

Financial KPIs can be calculated by using our cost of production calculators or by using the costings for herd performance that can be found on our Pork Costings and Herd Performance page.

Processes such as feeding will have multiple KPIs, ppkg is an obvious one but feed conversion ratio (FCR – kg feed/kg of pork) is also important. FCR is also a proxy measurement for environmental impact.

Monitoring performance when making changes

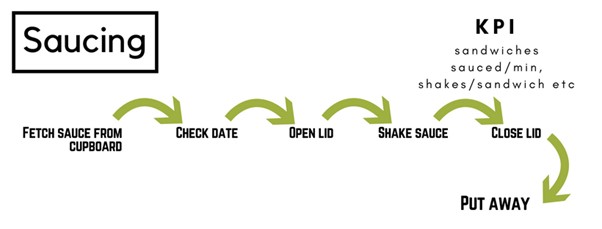

To monitor effective change, we use indicators which may be referred to as KPIs but are actually simple metrics that tell us if the outcome was successful or efficient.The first thing to do is agree with what steps make up a process.

As an example, we can refer back to the bacon sandwich process. Even a process as simple as saucing can be broken down into individual steps (see diagram).

In pig production, there is no difference, the processes of fertility, feeding and growth etc. all have steps that must be undertaken to complete the process. The diagram below shows an example of this.

Each step can be considered a work instruction/protocol/SOP and could be turned into a protocol with a number of metrics that can be used to check efficiency, e.g. number of non-productive days, number of returns etc.

With a clear protocol and a couple of metrics to check the effectiveness, small changes to the business that lead to efficiency savings can be implemented. It must be noted, however, that these metrics no matter how successful when benchmarked against previous performance or other producers, will not indicate the overall business performance.

For this you need to focus on the KPIs.

Cost of production and performance data and interactive tools

Hall, S. (2015) Basic Strategic Pig Production: The Breeding Herd. CreateSpace Independent Publishing Platform

Hall, S; Wellock, I & Jagger, S. (2013): The importance of key performance indicators for profitability.

Harris, C & Harris, R. (2018) Developing a Lean Workforce: A Guide for Human Resources, Plant Managers, and Lean Coordinators. International Pig Topics — Volume 28 Number 6

Hartman, B. (2015) The Lean Farm: How to Minimise Waste, Increase Efficiency, and Maximise Value and Profits with Less Work. Productivity Press.

Kotter, J. (2012). Leading Change. Harvard Business Review Press.

Kotter, J; Rathburger, H. (2016). That's not how we do it here!: A story about how organisations rise, fall - and can rise again. Penguin Portfolio.

Kotter, J; Rathburger, H. (2017) Our iceberg is melting: Changing and succeeding under any conditions. Macmillan Publishing.

Liker, J. (2004). The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer. McGraw-Hill Education

Redman, G. (2015). The best of British farmers, what gives them the edge? International Journal of Agricultural Management. Volume 4 Issue 4

Wilson, P; Harper, N & Darling, R. (2012). "Explaining variation in farm and farm business performance in respect to farmer behavioural segmentation analysis: Implications for land use policies". Land Use Policy Vol 30 pages 147– 156

Topics:

Sectors:

Tags: