Farmbench for better margins: How do the top 15% of suckler farms turn a profit?

Friday, 19 September 2025

Following on from our previous article on top suckler herd performance, we dive deeper into what separates those at the very top from the rest. We explore how the top 15% of herds cut costs, boost calf weights, and turn efficiency into profit.

Key areas for top 15%

- A focus on tight calving patterns allowed for improvements in herd fertility and stock management.

- Good cow nutrition and efficient feed use lead to strong calf daily liveweights

- Careful management of key overheads; labour, machinery and land, made cost of production the key driver for top 15% performance.

What is Farmbench?

Each year AHDB supports farmers to record their business performance through our online tool, Farmbench. Farmers can measure current performance and identify areas to build on by comparing to our national figures, while helping AHDB to better understand and support the beef and lamb industry.

The most recent national benchmarks for livestock production can be found on our cost of production page. Farmers can use these to start benchmarking their own business either individually or with the help of our regional Farmbench Managers.

What is included in this data?

This article analyses Farmbench data covering autumn calving 2023 and spring calving 2024. The average suckler herd net margin of each farm is ranked from highest to lowest. We compare an average net margin of the top 15% of farms to an average of the remaining 85%.

What do these top performing herds look like?

- Herd size on average was 160 cows, but herds as small as 30 cows made it into the top 15%

- All calved at 24 months, except one herd at 28 months

- All spring calving, except one farm which was 30% autumn calving and 70% spring calving

- The top 15% included farms in Severely Disadvantaged Areas (SDA) and Non-Severely Disadvantaged (Non-SDA) land, as well as organic and non-organic systems

Careful management of cow fertility

The top 15% focussed on managing herd fertility and calving efficiency. A short calving period of only 11 weeks meant that calves were close in age. In the North East, one of the top performers with a large herd said this allows easier calf management, with all worming, vaccinating and weaning happening at the same time. Finishing calving quickly also means that the top performers spend fewer weeks checking cows than the remaining 85% of farms.

Another benefit of a short calving period for the North East top performer was that the best breeding cows are selected naturally, and the least fertile are taken out the herd after missing the window. At least 75% of cows calved in the first 6 weeks of calving within the top 15%, whereas the remaining 85% had several farms which calved between 0–20% of cows in the first six weeks of calving, which could suggest poorer fertility, or less focus on managing the calving pattern. Cow condition also feeds into the short calving period on the top performing farms spoken to, using an easy calving bull to help reduce the stress of difficult calvings, as well as allowing cows at calve at a slightly higher condition score, so they recover and return to the bull quicker.

Efficient calf daily liveweight gain

The top 15% and remaining 85% both reared 0.89 calves per cow put to the bull. Daily liveweight gain is where the top group made an impact, rearing calves at 1.26 kg/day, to produce a weaned calf at 317 kg. This was 42 kg heavier than the calves from the remaining 85% of farms, which were also weaned 16 days later than the top group.

Importantly, these top farms used much less creep feed than the lower group to achieve these weights, only feeding 1 kg/head compared to 17 kg/day in the lower group. This suggests that the top 15% of farms are targeting feeding carefully and ensuring that the cow is rearing her own calf as efficiently as possible. The North East top performer said keeping cows with forage in front of them was a focus, to ensure they milk well, but additionally the rising plane of nutrition of spring grass helps fertility at bulling.

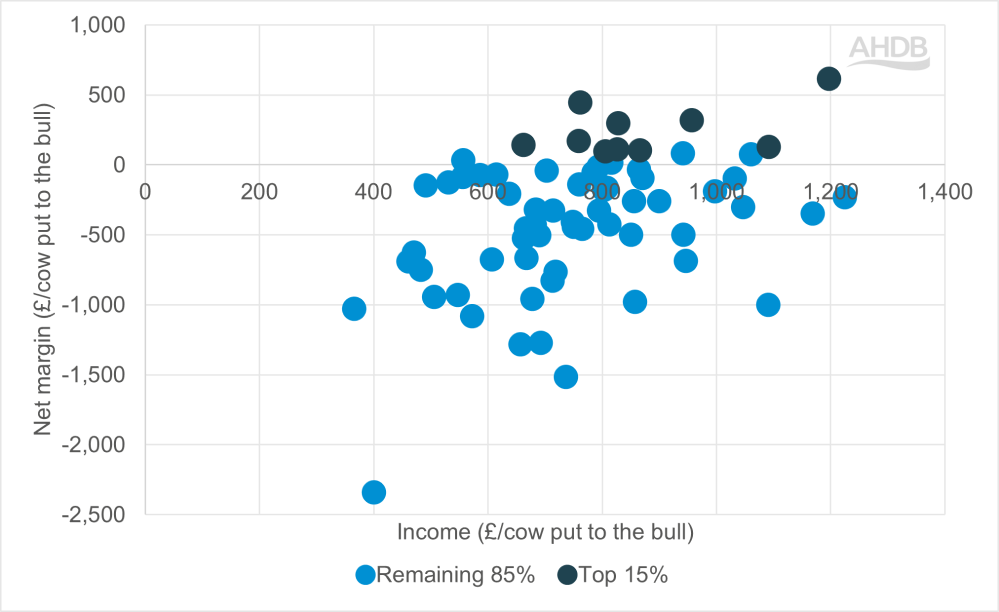

Achieving good weaned calf value

While strong markets over the last year have helped margins, top farms only achieved £0.08/kg more value on average on calves at weaning than the remaining 85% (£2.95/kg versus £2.87/kg). Income on top performing farms was driven more by calf weights than marketing. The top 15% of herds made a profit with an income of between £550 to £1,200 per cow put to the bull; equally farms with the same level of income made a loss. While income can boost margins, it isn’t the main driver for profitability.

Net margin and income per cow put to the bull

Source: AHDB

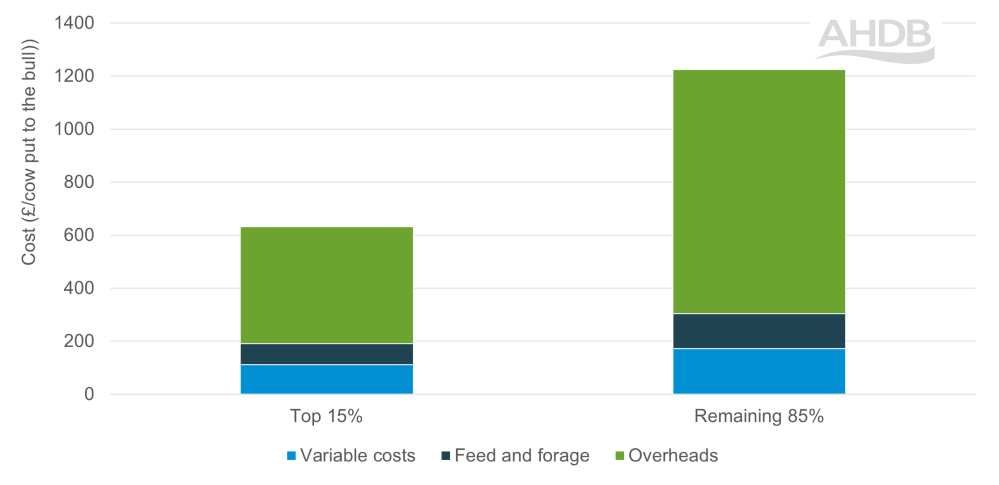

How the top performers spend

When it comes to production costs, the top 15% spent just over half the amount that the remaining 85% did to produce the same number of calves. How did they do this?

Top performing farms spent less in every cost type than the remaining 85%, resulting in a saving of £590 per cow put to the bull. Though the top performers made savings in feed, forage and variable costs, these were quite small as they maintained investment in areas that support output, such as feed and veterinary costs. While for the top 15%, lower feed and variable costs generated a saving of £113 per cow put to the bull, overheads were where these herds saved the most.

Cost of production per cow by cost type

Source: AHDB

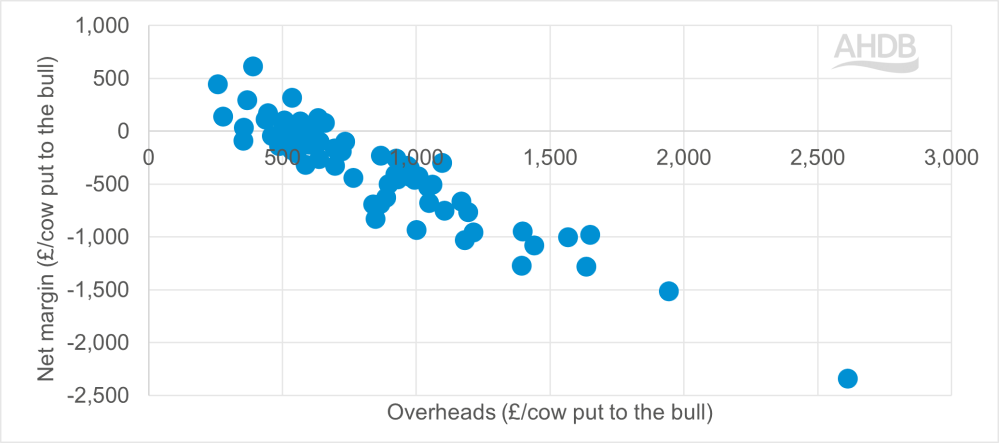

Overhead control is key, regardless of scale

Overheads (including labour, machinery, property costs, rent, and administration costs) make up most of the cost of production for a suckler herd and Farmbench data shows there is a strong link between lower overheads and higher profit. This can be related to the larger average herd size in the top 15%, however small herds can still control overheads. For example, the latest Farmbench data showed one top performing herd with around 30 cows had lower overheads per cow put to the bull than several larger herds in the remaining 85% with over 120 cows. The overhead costs in which top performers saw the largest savings were labour, machinery and rental values. Farmbench uses an imputed rental value on owned land, so there is a fair comparison with enterprises on rented land.

Net margin and overheads per cow put to the bull

Source: AHDB

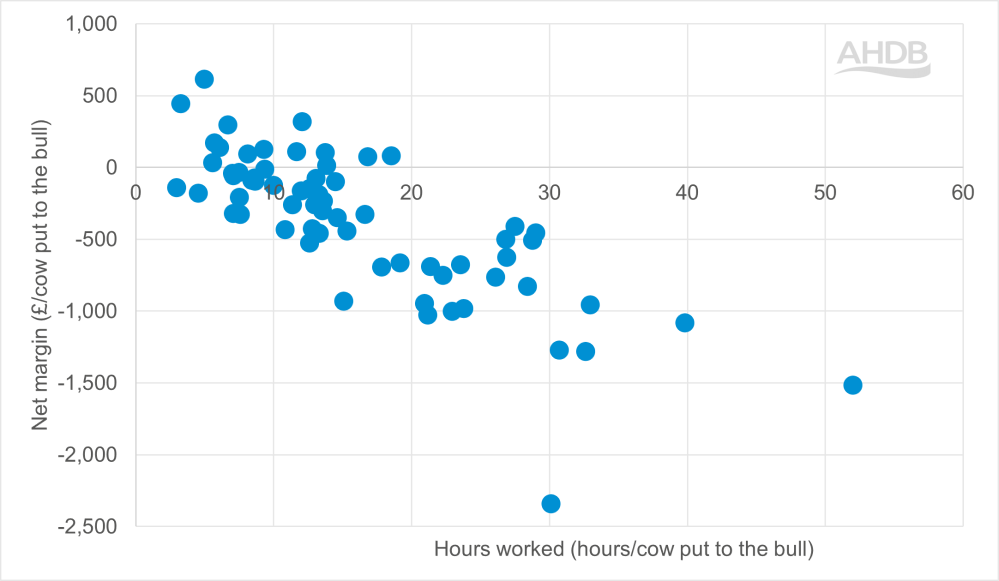

Reduced hours for higher profit

Farms with the lowest hours per cow tended to make the most profit, as they used labour efficiently and reduced costs. On average the top 15% spend half the time per cow that the remaining 85% did. Even the smallest farms in the top 15% spent less time per cow than the average 85% performer. Less time per cow was key to profitability in the top 15%, resulting in a labour cost of £148 per cow compared to £300 per cow in the remaining 85%.

Net margin and hours worked per cow put to the bull

Source: AHDB

Efficient machinery and land use

Machinery was used carefully on top performing farms, resulting in a saving of £132 per cow put to the bull. The largest differences were machinery repairs and equipment depreciation, suggesting top farms were focused on efficient use and replacement of kit. One of the top performers in the North East with a smaller herd size stated that they didn’t buy machinery new, and repaired breakdowns themselves to keep overheads down.

Similarly, top performing herds diluted land rental values over the herd as much as possible, maintaining optimum stocking numbers to use forage efficiently. This, alongside lower average value of the land the top performing suckler herds grazed on, helped them save £110 per cow put to the bull compared to the remaining 85%.

What are the top 15% doing differently?

The top 15% all made a profit on their suckler herd, on average this was £243 per cow put to the bull, which includes imputed costs, such as unpaid labour and a rental value on owned land. By comparison, only 7% of had a positive margin. The top performing farms all showed a focus on fertility and calf growth to efficiently produce a good weaned calf from their suckler cow. Cost management was critical, though the focus was primarily on controlling overheads rather than variable inputs or feed and forage. An extra 45% of the remaining 85% would have been profitable with no other changes than lowering overheads in line with the average top 15%.

Get in touch

The Farmbench tool is fully supported by AHDB through by our regional Farmbench Managers who can assist you in comparing your farm to the national dataset. Get in touch today to arrange a visit.

Our 2023–24 figures are available on our cost of production webpages. Visit these to start comparing.

Sign up for regular updates

You can subscribe to receive Beef and Lamb market news straight to your inbox. Simply fill in your contact details on our online form.

While AHDB seeks to ensure that the information contained on this webpage is accurate at the time of publication, no warranty is given in respect of the information and data provided. You are responsible for how you use the information. To the maximum extent permitted by law, AHDB accepts no liability for loss, damage or injury howsoever caused or suffered (including that caused by negligence) directly or indirectly in relation to the information or data provided in this publication.

All intellectual property rights in the information and data on this webpage belong to or are licensed by AHDB. You are authorised to use such information for your internal business purposes only and you must not provide this information to any other third parties, including further publication of the information, or for commercial gain in any way whatsoever without the prior written permission of AHDB for each third party disclosure, publication or commercial arrangement. For more information, please see our Terms of Use and Privacy Notice or contact the Director of Corporate Affairs at info@ahdb.org.uk © Agriculture and Horticulture Development Board. All rights reserved.

Topics:

Sectors:

Tags: